Continuous research and development

as well as establishment of

production facilities

for the future.

YEKUN has the largest facility in the domestic industry with about 6,600 square meters of space, and carries out operations through seven teams including metal molding, painting, and casting. YEKUN is not only focusing on design, but making constant efforts to realize actual products by generously investing in the latest technology.

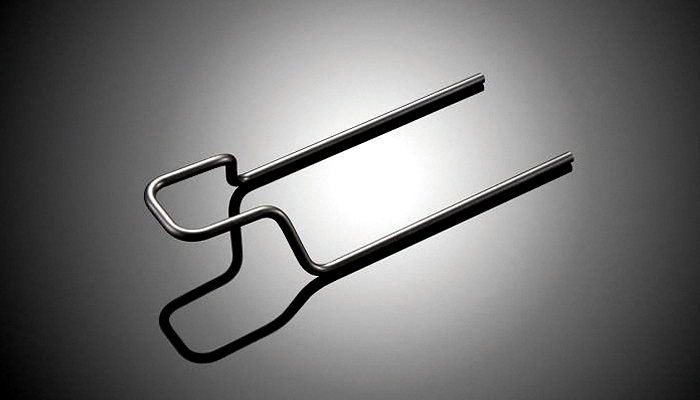

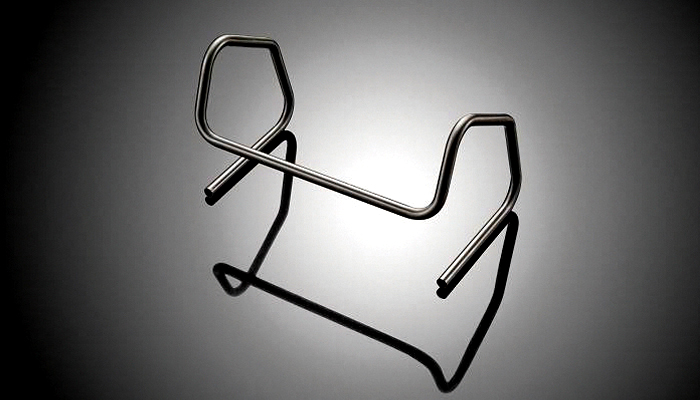

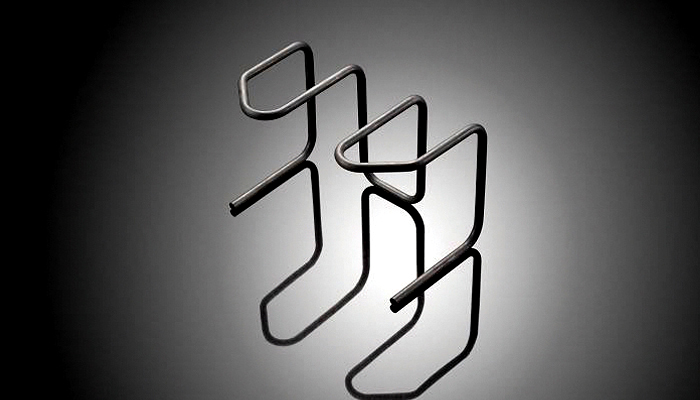

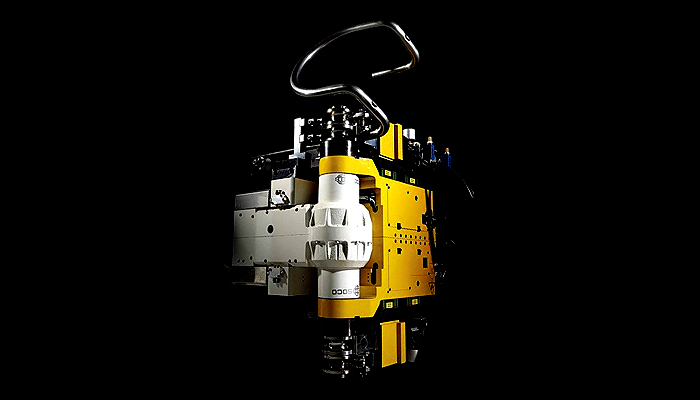

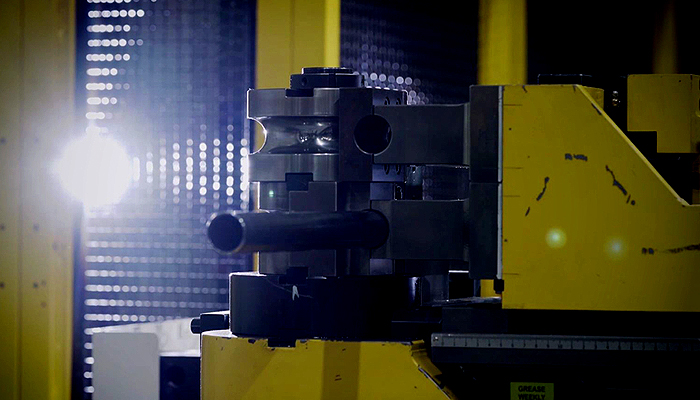

3D pipe bender

A sophisticated technology implemented in 3D that enables the production of flexible frames

- Outer diameter Maximum Ø50.8

- Working speed Bending 110/s Transfer 1,000/s Rotation 190s

- Effective pipe length 4,500mm

- Maximum bending angle 190

- Mold mounting up to 4 stages(2 stages each on the left and right)

- Permissible tolerance ±0.1mm

Aluminum gravity casting

Dissolvable up to 500 kg at once /

Produce outdoor bench casting with various molds.

Strength tester

Maintains high durability and quality through periodic self-tests.

The only equipment possessed in the industry.

Welding

YEKUN can produce various structures with equipment such as argon,

arc, CO2, plasma cutting machine, etc.

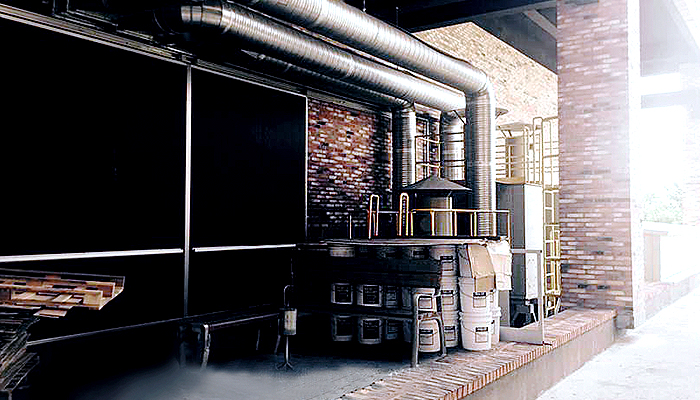

Dust collection facilities

As an eco-friendly company,

YEKUN has a dust collection facility that sucks fine dust inside the factory.